Talented young Nigerian students build a mini sports car in school, Africa has the potential to produce innovative and creative solutions with different techniques and results. Africa’s natural resources and ecosystem have fueled innovation in sustainable technologies, such as renewable energy, waste management, and eco-tourism.

The world we live in is so unpredictable that learning new things and being able to adjust to them, along with having creativity, problem-solving, and communication skills, are essential.

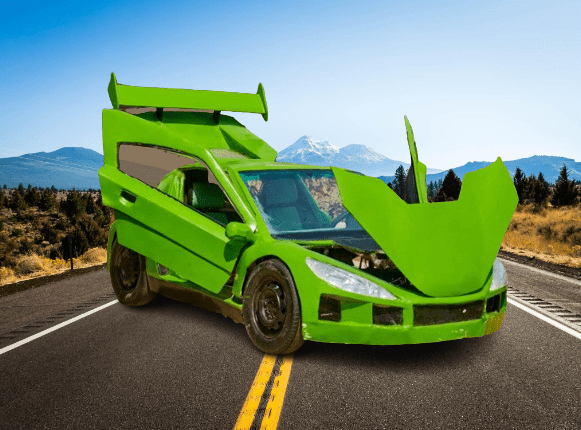

A team of graduates of the Mechanical Engineering Department University of Jos in Plateau State have built a mini sports car which they named Aspirer Espoler.

The team builds the car mostly from locally sourced materials with the help of some of their lecturers and Jeremy Benny’s automobile.

This green, locally manufactured small sports car is the final year project of a team of 500-level students in the mechanical engineering department at the University of Jos.

In January 2022 after the defense, news of the work made rounds on social media to the amazement of many Nigerians who celebrate their effort.

According to Dan Morgan the project team member, the name of the car is Aspirer Espoler and we got the name from the French name Aspir, It represents the concepts of striving and experiencing hope.

Therefore, we expect that Africa will eventually catch up to the rest of the world regarding automotive technology.

The team says that when it came time to start on their project and get to work, they wanted to be unique and collaborate to create something new.

Paul Johnson another project team member said When the project started, I promised most of my colleagues that it would take us places. When we were done, I told them that, through God’s grace, I wanted us to build an electrical automobile or a solar-powered car this year, and by God’s grace, we were able to attain that dream.

they started working on the project in May, even though there were fears they wouldn’t meet the deadline, but with their determination and support from those around them including their lecturers, they were able to complete it in due time.

Wisdom Ikenna one of the project members maintained that at first, most of the lecturers were not too direct with us, because they knew that the time frame was not on our side.

Then secondly there was not any positive vibe coming from most of them, but I believe that they had our back.

Austin Koniv a member of the project team, said my department is from the institution that gave us support, initially

though they were concerned with us being able to meet up on time with the project.

But as time went on, we kept telling them that we would meet, and they gave us that trial, and the outcome of the work was great.

so, for them being able to give us that chance and that trial alone, I can commend them for that they supported us very well.

Austin maintained that in terms of our other aspects like our designs, they kept on supervising us, to make sure, we got it right.

Engr Adesanmi Adegoke the project supervisor of the Department of Engineering Unijos, said that being a fan of Cars, I love this project, but I can tell you, it won’t be easy because you don’t find the design of cars in textbooks. After all, it’s patented to the companies.

They don’t release their secrets, so it means that you have to apply the knowledge from the classroom, for the design, I think this is great.

Adegoke says, that if you guys think that you have learned enough which we know that we have taught you guys enough, then go ahead, but the finance also, I hope you guys are up to task, they say yes. I said well then go ahead; I’m ready to supervise you guys.

Many would wonder how they got inspired to embark on such a project and the response brings in Benny’s automobile into the story.

in 2020 Jerry Malo the current leader at Benny Automobile built the first Nigerian carbon fiber sports car named Benny Pury, and so tapping from his pool of knowledge through an internship with him, the team was able to build theirs.

Dan said that Benny Automobile the person of Jerry Malo has inspired us in so many ways, like he exposed us to a lot of things and made us realize that we can achieve these things without thinking like there is something that is not achievable.

During our 300 level, we went to a conference he organized, and during that conference, we had lectures, he did the lectures for us, and during those lectures, We became interested in him when he showed us some of his works and exposed us to a range of topics. Thus, we decided to pursue our CSE at the company’s 300 level.

After their internship they decided they wanted to build a car, A car model as their graduating project, I was happy when they said that, and I tried to Enlighten them about some of the challenges that most likely would be facing.

My team did our best to support them in the project and we took a lot of time, we gave them personal dedication, and we dedicated a lot of effort to seeing that they learn the knowledge not just doing it, not just us doing it for them.

we do our best to explain why they need to use this material and we make sure that they do it themselves at the end of it they were successfully able to build a car prototype, and it was a happy beginning for them.

I just hope that they will continue developing and building on that foundation.

most of the materials used were sourced locally with a lot of Trials and errors, but it was a learning card for them, each member of the team had a role to play, all to ensure that their project was a success.

Wisdom said that what he did, was to work on the car body, what we did was we got the artificial clay, the clay was then soaked in the drum, the soaking was done for a minimum of 6 hours, after it was done, we carried out needing, the purpose of the needing was to eliminate the Lumps in the clay. after the Lumps were eliminated, we deposited the artificial clay directly on the chassis body.

at that stage, we allowed the clay to drive for a minimum of 2 days, then we started the initial caring.

Oke Blessing one of the project team said his major role in the project was to achieve the exterior aspect of the project, bringing out the beauty of the project.

Austin maintains that where he contributed more was on the body, the molding and layering of the fibers.

then bringing out the shell of the body, and then joining the body into a single unibody, then joining it to the chassis frame that was constructed.

According to one member of the project team, Chinonso Duru said she did more of the sourcing of the clay, getting off the cylindrical pipes for the chassis, and the metal Steels, we use standard Parts just like the engines, the transmission, the braking system, the headlamps, all those parts were standard, was not made by us.

but the body was made by us, like the clay, and the fiberglass, we use the POP to make up those materials, and I play a key role in souring them.

Jeremiah James a project team member maintained that he carried out the concept designs for the car body and the chassis.

we built the chassis from scratch, with local Source materials, and also, we built the body.

we got all that from the base plan of the project which was from the concept designs, and I was in charge of the beauty on the inside.

Paul maintains that he was in charge of the Interior, I make sure that the inside is not just only comfortable to the eye or good to the eye, and I ensure it is hygienic and safe.

The challenges

the journey was indeed a tasking one, and it seemed they had no idea what it would take from them when they first started.

Blessing said that the biggest challenge was the funding aspect of the project, the financial aspects were at some point, we were short of funds, and we were asking how we were going to complete the project.

but we were able to skip through it, we added some money to paint the car and do the interior part.

one could have expected the issue with the funding they had, but there were other challenges they didn’t envisage.

One of the largest obstacles was sourcing the materials; occasionally, the color you receive is not what you wanted because the interior is where everyone sits, and it must be aesthetically acceptable.

Getting this material was quite challenging because we had to ensure it was visually appealing and a nice color.

even though they say they got great support from their lecturers, their initial reaction wasn’t the same, it felt like they were embarking on a Herculean task, but in the end, they were all proud of their achievement.

ALSO : UNIVERSITY FIRST-YEAR STUDENTS FACE ACCOMMODATION CRISIS

Prof. Danjuma Dajas the dean of, the faculty of engineering Unijos disclosed that we try to encourage Innovation as well as the practical implementation of engineering solutions by our students, because we realize the way the country is going, the way the labor market is going, we have to ensure that we train students whom themselves can provide Solutions rather than going out there to look for white color jobs.

we are glad that at least a great percentage of our students assimilated this particular principle in the faculty, and we are working towards it, that’s why we’re getting results, and we hope to do better.

According to Engr, Kamtu Peter, the coordinator, of the mechanical engineering department, Unijos who said, when this project came up, we were excited, we put ourselves together, we know we had given them the basis that is the theory of aspect of it, of which not only car, if they feel they can develop and fly an airplane, they have the knowledge that’s what the department has done over these years from 100 level to 500 level.

The knowledge they have acquired is only possibly the missionaries that could limit them, they can go anywhere or do anything within the conference of mechanical and theoretical aspects that we have given them.

so we are not surprised because we know we have given them theoretically, so when they came up with this we’re excited we give them all the support.

Dr, Ede Godwin, the project coordinator department of Mechanical Engineering Unijos, said that they want to train students who will be independent, and who will be able to fly the flag of mechanical engineering in the labor market. So I expect them or believe that they will take this knowledge they have acquired to establish themselves to become independent entrepreneurs.

we should have several innosons in Nigeria because we have the brain work and the capability.

building a car from scratch was not easy to work, but for the team, it was just the right push they needed to dive into the automobile industry.

Blessing stated that he has been passionate about cars since he was a child, thus having to work on this project was a huge dream of mine. I now picture myself pursuing a career in the automotive sector.

with their creativity and Zeal, these young minds have once again proven that there exists raw and brilliant talent in Nigeria. with the right support from the government, they can develop their knowledge and do more amazing things for the benefit of the country.

3 thoughts on “Young talented Nigerian students BUILD A MINI SPORTS car on campus”